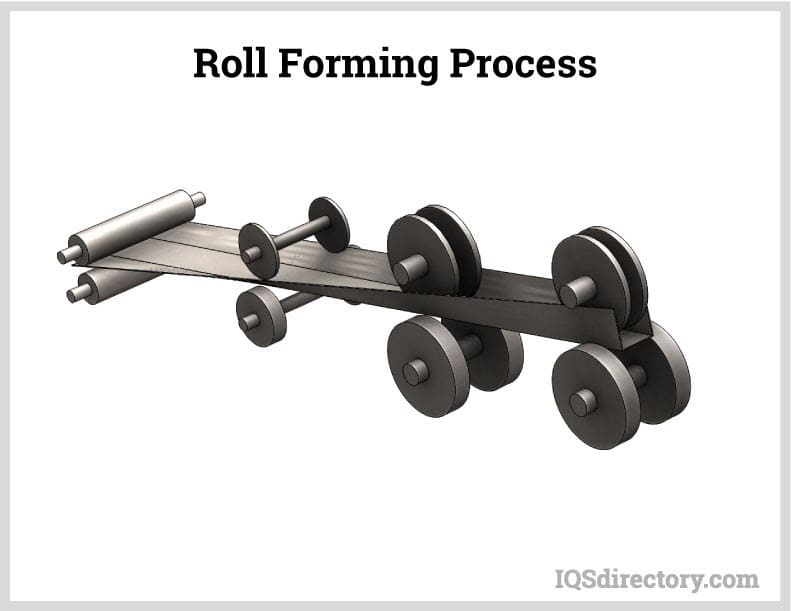

Roll Forming Process - It’s worth learning about how it works. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. A roll former may appear to be a complex machine, with its array of stations and high speeds. Unlike most forming operations which have various. Web what is roll forming and the roll forming process? Web roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation.

Roll forming YouTube

Web roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. A roll former may appear to be a complex machine, with its array of stations.

Steps of the Roll Forming Process

Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. A roll former may appear to be a complex machine, with its array of stations and high speeds. Unlike most forming operations which have various. Web what is roll forming and the roll forming.

What is the Roll Forming Process? Rollforming Machine

A roll former may appear to be a complex machine, with its array of stations and high speeds. Web what is roll forming and the roll forming process? Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. Web roll forming is one of.

Roll Forming as a Bending Process in Metal Fabrication

Web roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. A roll former may appear to be a complex machine, with its array of stations.

What is Roll Forming? National Material Company Steel Processing

Web what is roll forming and the roll forming process? It’s worth learning about how it works. A roll former may appear to be a complex machine, with its array of stations and high speeds. Web roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Web roll forming is a continuous.

What is "Roll Forming?" The Chicago Curve

Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. A roll former may appear to be a complex machine, with its array of stations and high speeds. Web roll forming is one of the few sheet metal forming processes requiring only one primary.

EMARC Group Roll Forming Process

Web what is roll forming and the roll forming process? Web roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. It’s worth learning about how it works. Unlike most forming operations which have various. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive.

How Roll Forming and Tubing Works Kloeckner Metals Corporation

Unlike most forming operations which have various. Web what is roll forming and the roll forming process? A roll former may appear to be a complex machine, with its array of stations and high speeds. It’s worth learning about how it works. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets.

What is roll forming and why do I need it? Wuxi Taihu Machinery

Web roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. A roll former may appear to be a complex machine, with its array of stations and high speeds. Web what is roll forming and the roll forming process? Web roll forming is a continuous process which converts sheet metal into an.

Roll Forming Process Ultimate Guide 2020 Concept to Production

A roll former may appear to be a complex machine, with its array of stations and high speeds. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. Web what is roll forming and the roll forming process? Unlike most forming operations which have.

Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. It’s worth learning about how it works. Web roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Unlike most forming operations which have various. Web what is roll forming and the roll forming process? A roll former may appear to be a complex machine, with its array of stations and high speeds.

Unlike Most Forming Operations Which Have Various.

A roll former may appear to be a complex machine, with its array of stations and high speeds. It’s worth learning about how it works. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. Web roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation.